Optimising purchasing and goods receiving with inventory metrics

Inventory metrics are simple indicators used to track and improve inventory management stock. They are often compared with past results or industry standards. Important factors include product type, quantity, storage location and how long goods are stored.

Businesses need enough stock inventory to meet customer demand, but too much stock increases costs and ties up cash. This balance is a key part of any manufacturing inventory management system or retail stock management system.

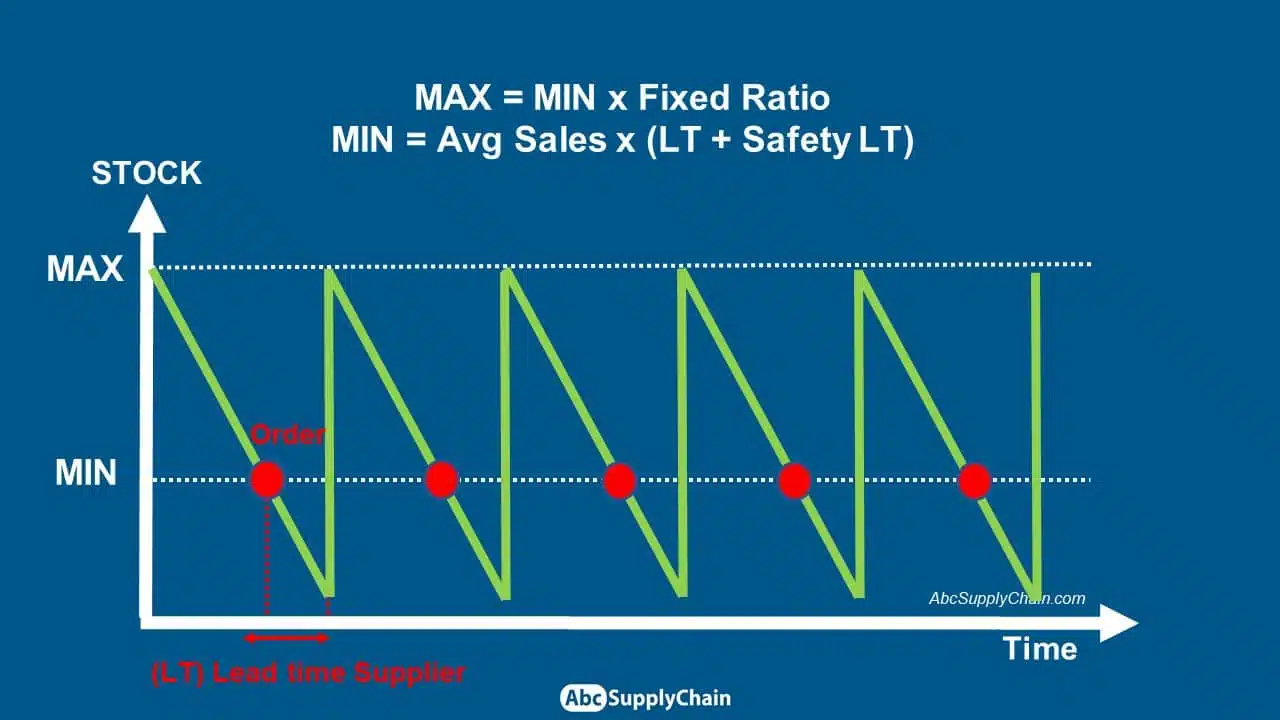

For this reason, inventory levels are usually managed using three values: minimum stock, reorder point, and maximum stock.

Minimum stock

Minimum stock, also called safety stock, helps keep products available when deliveries are delayed or demand suddenly increases. Recent disruptions, such as pandemics or post-Brexit customs delays, have shown why this buffer is important.

Minimum stock is not a fixed number. It should be reviewed regularly using past data and risk factors. To calculate it, businesses need to know the average delivery lead time and the average daily usage.

Example:

If delivery takes 7 days and daily consumption is 50 units, total usage during that time is 350 units. In this case, the minimum stock level is 350 units, often calculated using a simple safety inventory formula.

Reorder point

The reorder point, also known as the reorder level, is the stock level at which a new order should be placed. This ensures that minimum stock is not used up before the next delivery arrives.

The reorder point formula is simple:

Daily consumption × lead time + minimum stock

Example:

50 units × 7 days + 350 units = 700 units

This level is often shown in an inventory control chart or inventory control diagram to help teams reorder on time and avoid running out of stock. Knowing how to get average inventory is especially important for accurate planning in small business inventory management

Maximum stock

Maximum stock is the highest amount of inventory a business should hold. It is partly limited by warehouse space, but also by cost. Even if space is available, too much stock ties up cash and increases financial risk.

Maximum stock is calculated using minimum stock and the optimal order quantity:

Maximum stock = minimum stock + optimal order quantity

The optimal order quantity depends on purchase and storage costs and is set by each business. Many companies calculate this using tool built into a manufacturing inventory management system.

Example:

If the optimal order quantity is 1,000 units and the minimum stock is 350 units, the maximum stock level is 1,350 units.

Clear inventory metrics help businesses keep products available, reduce tied-up capital and improve supply chain stability. In both manufacturing and retail, strong inventory management based on minimum stock, reorder point and maximum stock supports efficient day-to-day operations.

For more ideas on inventory management, europages Inside Business offers helpful tools and inspiration.